Cooling towers operate as large-scale heat exchangers, often placed atop a building, blowing air across a coil to remove heat. A chiller, meanwhile, is a large piece of industrial equipment located inside a building. There are many different types of chillers, yet all chiller models will contain an evaporator and a condenser.

How Do Cooling Towers And Chillers Work Together?

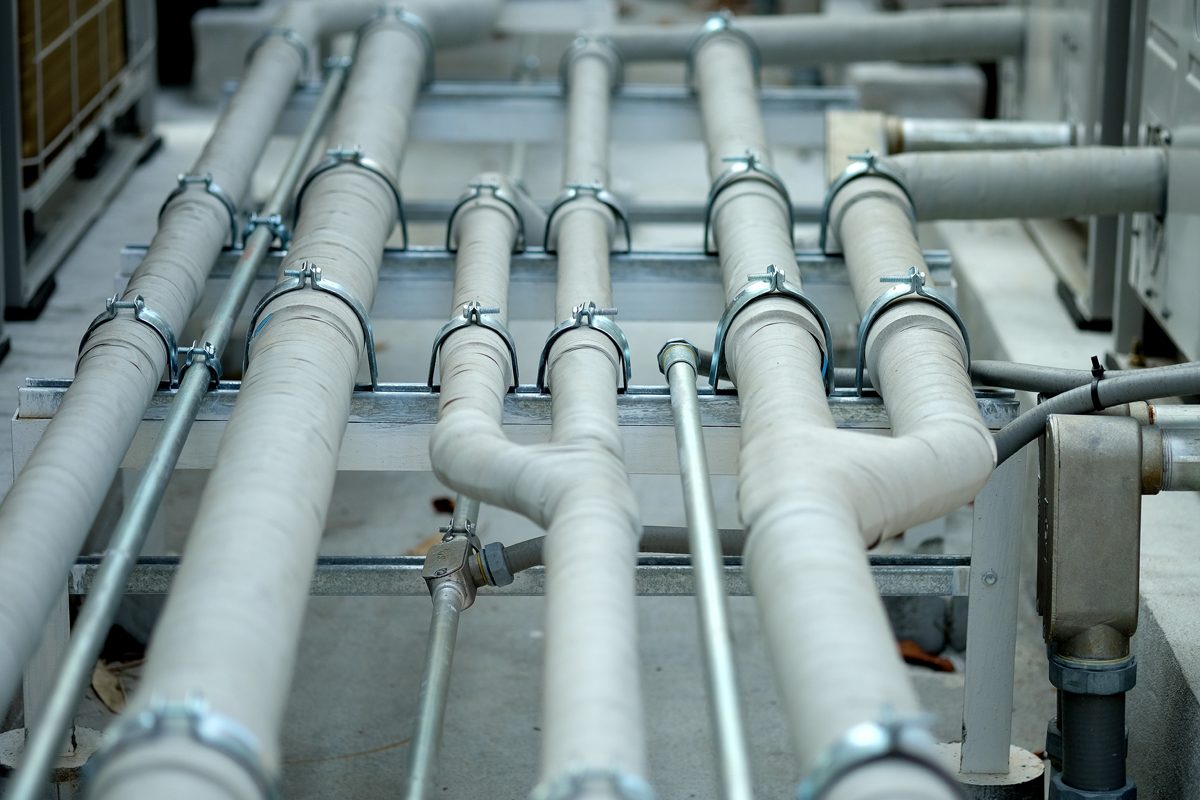

Working together, chillers and cooling towers make it possible to air condition large areas. In the chilled water system, the evaporative cylinder creates the cold water used for air conditioning. The chilled water (usually 45 degrees Fahrenheit) travels upwards to the riser, where it branches off and into air handling units found on several floors within a building.

This system features water flowing through a coil inside the air handling unit, with indoor air blowing over it. The heat that is transferred from the air to the water will then leave cooler air to circulate throughout the building. The water is about 55 degrees F by the time it flows out of the coil.

Condensed Water System

The condenser cylinder is connected to the evaporator cylinder in this system. The connection keeps the heat moving out of the evaporator and into the condenser. Yet, these two water lines will never interact with one another. Condenser water is warm water that travels up to the riser at about 95 degrees F. From there, the water heads towards the cooling tower located on the roof.

Once in the cooling tower, the condensed water will flow through the tower while fans pull in ambient air used to transfer heat out of this water. The condenser water will then return to the condenser cylinder more than 20 degrees cooler than when it first entered the tower.

Chiller And Cooling Tower Sizes

Multiple cooling towers and chillers may be needed depending on the size and layout of the building. Many sites, for example, will include redundant systems to prevent a building from going out of service if one part breaks down or fails. This failsafe will also allow for maintenance and repairs to take place while the cooling system is in operation.

Cooling Tower And Chiller Differences

Within chillers, heat is removed directly from the coolant. The heat is then transferred to the surrounding air. This is an essential part of any cooling process. Cooling towers, meanwhile, remove heat from water that is discharged from a condenser. Any plant or factory that happens to choose a system that is not appropriate for the area will have trouble properly cooling their surroundings.

While chillers and cooling towers do produce similar results, the slight differences between the two systems are why they are used in different settings. Cooling towers are generally used in oil and gas refining plants, thermal power stations and power plants neighboring bodies of water. Chillers are found in plastic-industry applications, microbreweries and wineries.

Types Of Chiller

There are two main types of chillers used today:

- Water-Cooled Chillers

- Air-Cooled Chillers

Cooling Tower Types

There are many more versions of cooling towers than chillers. Here is a list of the common models on the market:

- Crossflow Cooling Towers

- Forced Draft Cooling Towers

- Induced Draft Cooling Towers

- Factory Assembled Cooling Towers

- Counterflow Cooling Towers

Cooling Tower Installation, Replacement, & Refurbishment in Arizona & Nevada

Our team offers complete cooling tower refurbishment that will save your company tens of thousands of dollars over buying and installing new cooling towers. Cooling tower refurbishment and rebuilding adds about another 15 years of life to your equipment and helps you get your money’s worth out of your original investment in your cooling tower or property. We offer cooling tower installation, replacement, and refurbishment in Arizona and Nevada. We also sell other cooling tower parts and products.